DSL-8 Lane B Type In Stock, Delivery in 7 Days, and Counting Accuracy >99.80%. Bottling Capacity Upper to 55 Bottles/Min. It is widely used in the candy industry. It can quickly count and package all kinds of candies, effectively improve the efficiency of point packaging (equivalent to the work efficiency of 5 workers), and effectively avoid excessive filling caused by the inability to accurately control the quantity of weighing packaging. material waste. Improve production efficiency and save production costs for enterprises.This machine is suitable for counting and packaging various small-granule products such as food, pharmaceuticals, chemicals, etc. The packaging method can be bottled or bagged, which can replace traditional weighing packaging to achieve precise counting, fast packaging, and stability. production capacity.

Product Name :

BA-DSL-8Pro 8 Lane Capsule And Tablet Counter Counting MachineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

Tablet:Φ3~25mm ,pill:Φ3~20mm, hard capsule/soft capsule:000~5#After-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

This model is the seventh generation innovative product of our company .It can pack all kinds of tablets and capsules (transparent or opaque hard capsules, soft capsules, pills, etc.) in the range of 3-25 mm.Meet the requirements of GMP.It can be connected with bottle unscrambler, paper inserter, desiccant inserter, capping machine, aluminum foil sealing machine and labeling machine.

Main Features:

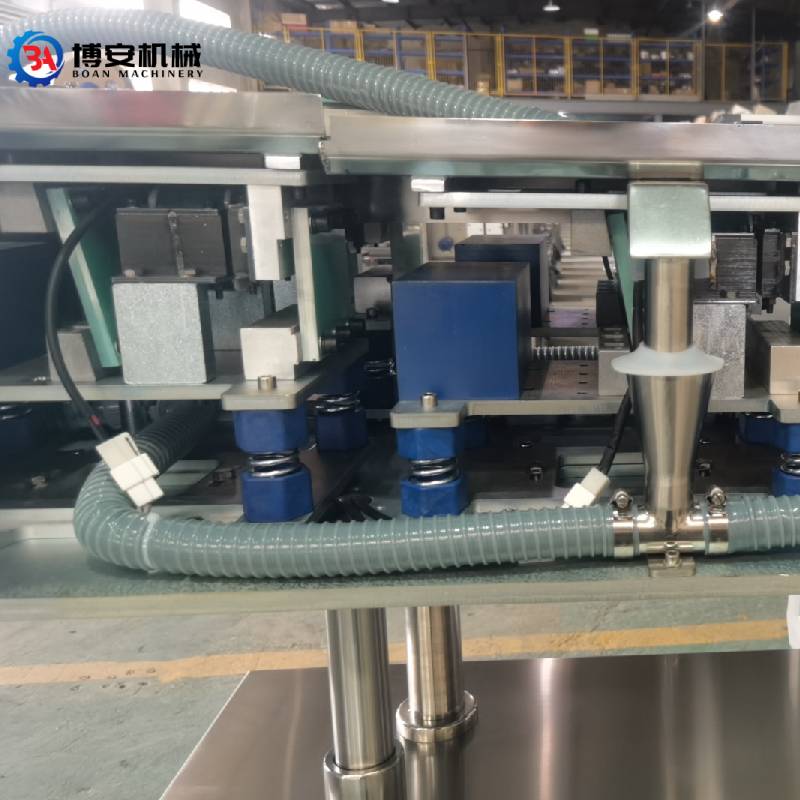

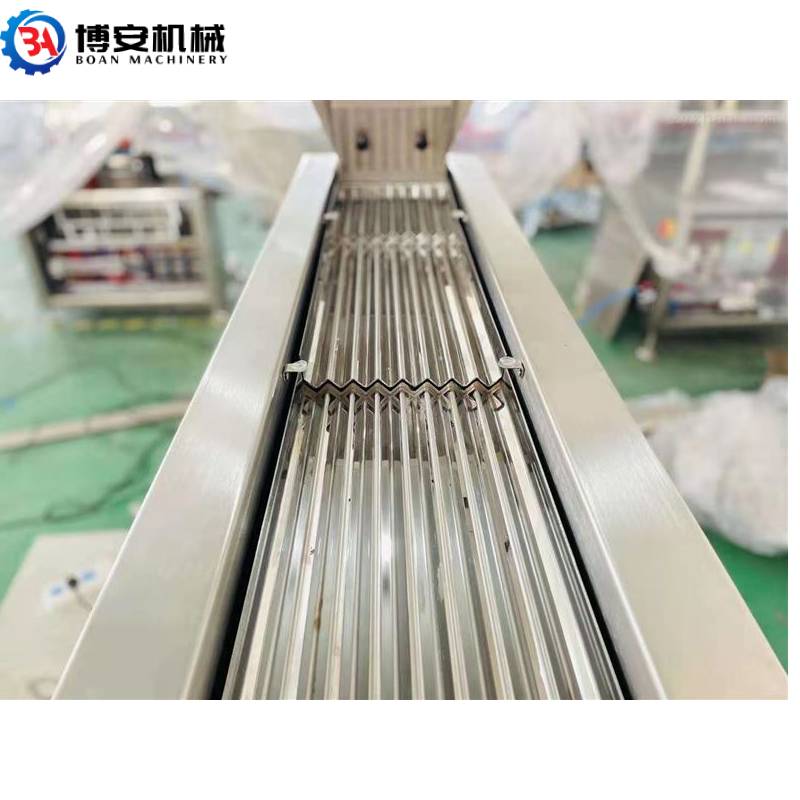

This product uses the principle of photoelectric induction to count, divide and transport the sensed pharmaceutical particles, and can monitor and set all the operating data in real time. The product is an 8-channel machine, that is to say, there are 8 vibration "V" grooves on the vibrating plate of the worktable, which can work at the same time, and use the vibration effect to automatically transfer the particles into the lower hopper to count one by one.

1. The chassis mainly plays the role of supporting the vibrating magnetic block, vibrating tank, hopper, conveying track, etc. At the same time, an electrical power distribution system is installed in the box.

2. The main function of the electromagnetic vibrator is to flatten and separate the particles from the hopper, so that the preparations for counting are now divided into two groups.

3. The operation panel is installed on the right side of the chassis, and can be touched on the panel

Setting of equipment parameters, start and stop operation, real-time data monitoring, fault alarm inspection and so on.

4.The silo is equipped with a stirring slurry to prevent the gummy from sticking in the silo and blocking the discharge port

5.The The feeding opening is made of PTFE material, double bow bending design, easy to feed the gummy and candy.The funnel is raised higher, and controlled by a large valve, which can prevent gummy from being blocked in the funnel.

Main Technical Parameters:

|

Model |

BA-DSL-8D |

|

Vibration groove tracks |

8 lane |

|

Production capacity |

70 bottles per minute (according to the capacity of 60 capsules per bottle) |

|

Counting Precision |

>99.97% |

|

Filling range |

3 ~ 9999 grains |

|

Applicable target |

Tablet:Φ3~25mm ,pill:Φ3~20mm, hard capsule/soft capsule:000~5# |

|

Applicable bottle type |

Φ25~75mm round and square bottle, height ≤240 mm |

|

Voltage |

AC380V 3P 50/60HZ |

|

Power |

1.8KW |

|

Pressure |

0.4 ~ 0.6Mpa |

|

Air consumption |

120L/min |

|

Hopper capacity |

45L |

|

Weight |

540kg |

|

Outline dim.(mm) |

1200×1400×1800 mm(L*W*H) |

About us :

Partners :