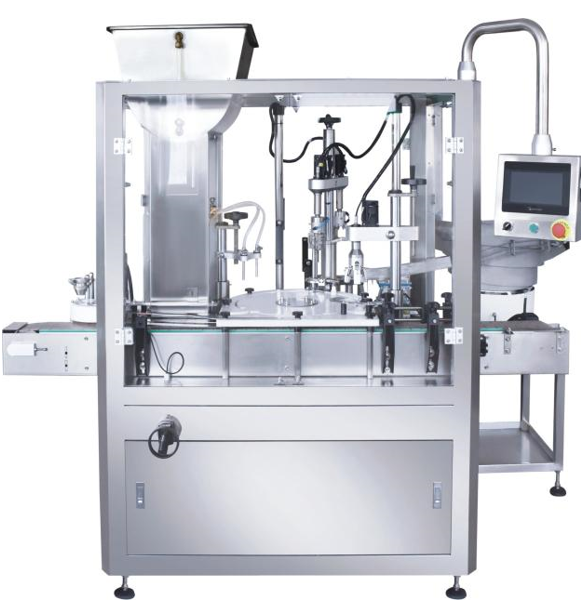

the LFCP-35 Auto High Speed Filling & Capping Machine is a powerful and high-performance packaging equipment that is widely used for filling and sealing a variety of liquid products across various industries.

Product Name :

Auto High Speed Filling & Capping MachineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

10-100mlAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

Key Features:

Uses an advanced PLC control system for automated operation.

High-speed filling and capping, capable of 35-45 containers per minute.

Can fill a variety of liquid products, such as beverages, dairy, cosmetics, etc.

Can be equipped with various sizes of filling heads and capping heads to accommodate different container sizes.

Automated container feeding and discharging system to improve production efficiency.

Provides a high degree of sealing and sanitation to ensure product quality.

Key Application Areas:

Food and beverage industry

Cosmetics and personal care industry

Pharmaceutical industry

Cleaning products industry

Main Features

1. Automated Operation:

The machine is equipped with an advanced PLC (Programmable Logic Controller) control system, which enables fully automated operation.

This allows for consistent and efficient production without the need for manual intervention.

2. High-Speed Performance:

The machine can achieve a filling and capping speed of 35-45 containers per minute.

This high-speed capability significantly improves the overall production output and efficiency.

3. Versatile Filling Capabilities:

The machine can handle a wide range of liquid products, including beverages, dairy, cosmetics, and pharmaceuticals.

The interchangeable filling heads and capping heads allow the machine to accommodate different container sizes and shapes.

4. Automated Container Handling:

The machine is equipped with an automated container feeding and discharging system.

This feature streamlines the production process by eliminating the need for manual container handling, further enhancing efficiency.

5. Sealing and Sanitation:

The machine is designed to provide a high degree of sealing and sanitation, ensuring the integrity and quality of the packaged products.

This is particularly important for industries such as food, cosmetics, and pharmaceuticals, where product safety and purity are critical.

6. Compact and Durable Design:

The machine has a compact footprint, measuring 1800 x 1300 x 1800 mm, making it suitable for various production environments.

The robust construction and high-quality components contribute to the machine's durability and reliability.

These key features make the LFCP-35 Auto High Speed Filling & Capping Machine a versatile and efficient solution for high-volume liquid product packaging across multiple industries.

Protective cover(stainless steel + plexiglass)

Conveyor belt

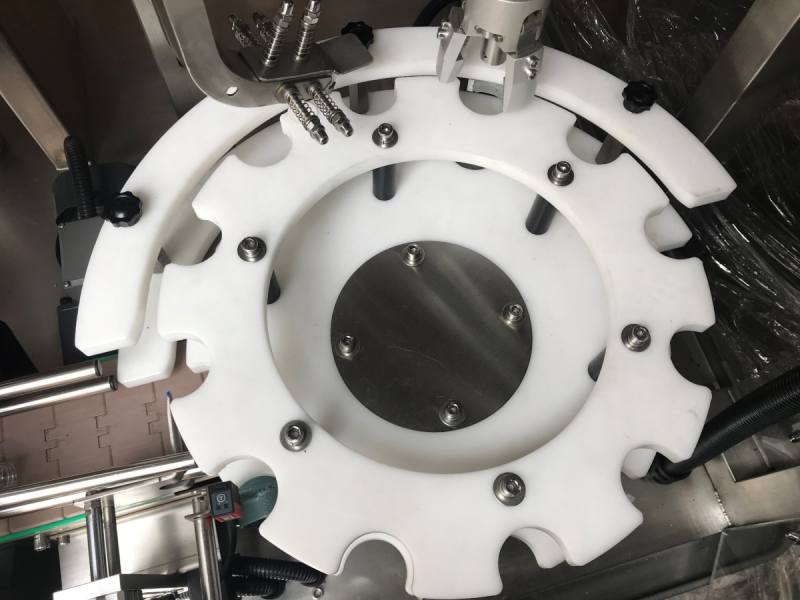

Rotary Table

Filling and Capping

Capping head system

Filling Nozzle System

Capper Feeder and Guide

Main Technical Parameters

|

Machine model |

BA-LFCP-35 Auto High Speed Filling & Capping Machine |

|

Control system |

PLC & Touch Screen |

|

Filling Speed: |

35-45 bottles/minute |

|

Filling Accuracy |

10-100ml, ≤±1% 100-1000 ml, ≤±1% |

|

Power Supply |

380V/50Hz |

|

Total Power |

4.5 KW |

|

Total Weight |

800 kg |

|

Overall Size |

1800 x 1300 x 1800 mm |

Certificates and Factory

Partners