Double head auger powder filling machine is a device used for the precise filling of powdered materials, widely utilized in industries such as pharmaceuticals, food, and chemicals.

Pharmaceutical Industry: Filling of powdered medications.

Food Industry: Packaging of spices, coffee powder, and other food products.

Chemical Industry: Filling and packaging of chemical powders.

This equipment is increasingly valued in modern manufacturing for its ability to enhance production efficiency and product quality.

Product Name :

BA-PF double head auger powder filling machineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

30g~3000gAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

Double head auger powder filling machine line is an integrated system designed for the efficient and precise filling of powdered products into containers. This line typically consists of multiple components that work together to streamline the filling process in various industries, including pharmaceuticals, food, and chemicals.

Key Components

1. Double Head Auger Filling Machine:

The core of the line, featuring two auger heads that allow simultaneous filling of two containers, improving throughput.

2. Hopper:

A storage unit that holds the powdered material before it is fed into the filling machine. It ensures a constant supply of material for uninterrupted operation.

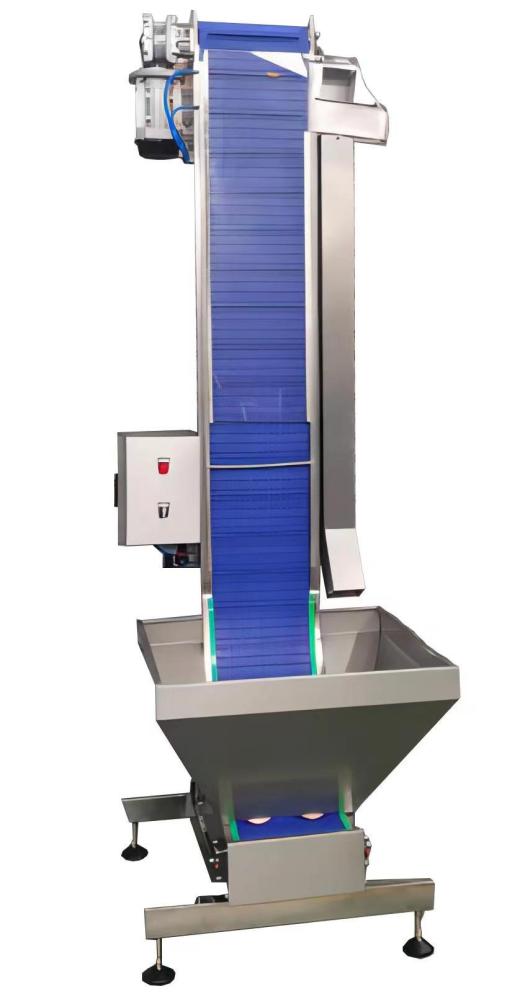

3. Conveyor System:

Transports containers to and from the filling machine. This system can include belt conveyors or other types of conveyors for efficient movement.

4. Control Panel:

An integrated control system that allows operators to set parameters such as filling speed, volume, and machine operation modes. Often equipped with a touchscreen interface for ease of use.

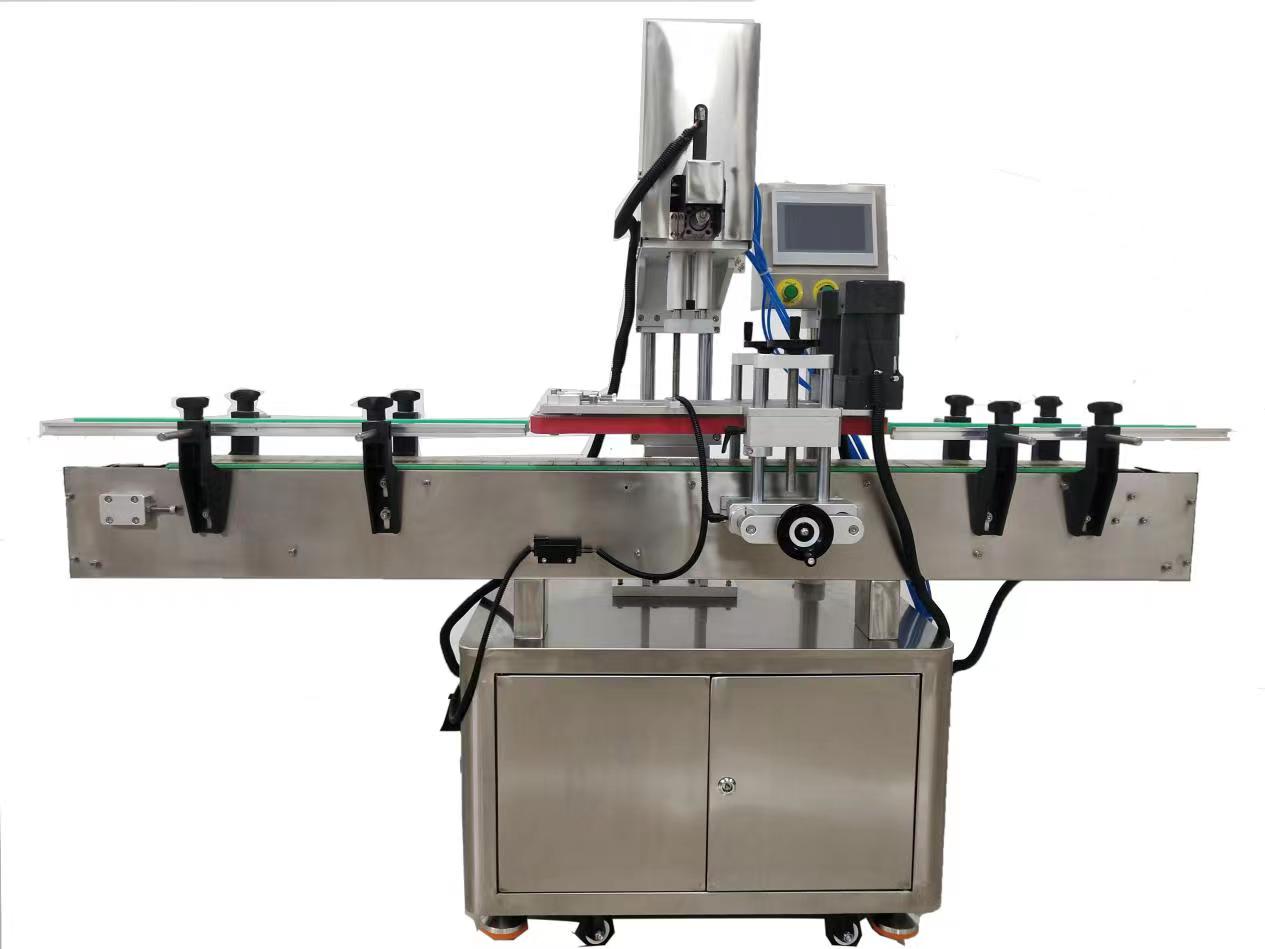

5. Capping/Sealing Machine (optional):

Automatically caps or seals the filled containers, ensuring product integrity and extending shelf life.

6. Labeling Machine (optional):

Applies labels to the containers after filling and sealing, facilitating branding and product information compliance.

Main Features

Key Features of the Double Head Auger Powder Filler Machine Line

1. Double Head Design:

Allows simultaneous filling of two containers, significantly increasing production efficiency.

2.High Precision Filling:

Equipped with advanced sensors and control systems to ensure accurate and consistent filling volumes.

3. Versatile Hopper:

A large-capacity hopper that can accommodate various powdered materials, ensuring a steady supply for continuous operation.

4. User-Friendly Control Panel:

Features a touchscreen interface for easy operation, enabling quick adjustments to filling parameters.

5. Adjustable Filling Speed:

Allows operators to customize the filling speed based on production requirements, enhancing flexibility.

6. Automatic Conveyor System:

Efficiently transports containers to and from the filling station, reducing manual handling and improving workflow.

7. Hygienic Design:

Constructed from materials that meet industry hygiene standards, making it easy to clean and suitable for food and pharmaceutical applications.

8. Optional Capping and Labeling:

Can be integrated with capping and labeling machines to streamline the entire packaging process.

These features make the double head auger powder filler machine line an efficient and reliable choice for high-volume powder filling operations across various industries.

Level Spit Hopper

Screw Type

Stainless Steel Type

Automatic Level Sensor

Hand Wheel

Screw Feeder

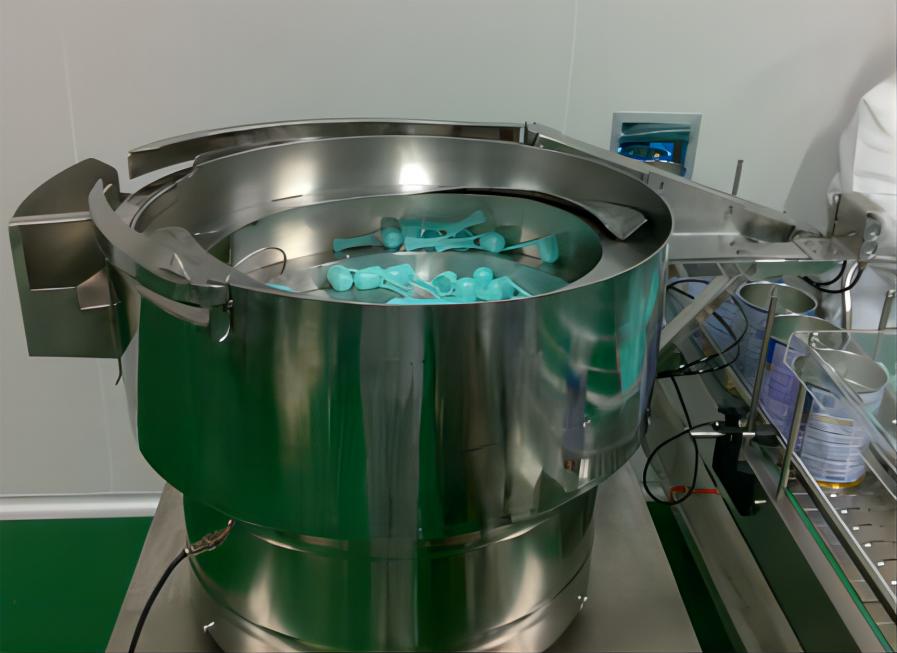

Automatic spoon feeding machine

Cap lifter

Continuous Aluminum Foil Sealing Machine(Electromagnetic induction sealing)

Capping Machine

Round bottle labeling machine

Augers and drill pipes

Main Technical Parameters

Dual heads automatic auger filler machine

|

Packing specification: |

30g~3000g (need to change the spiral) |

|

Packaging precision: |

±0.5-1% |

|

Applicable materials: |

powder |

|

Theoretical packing speed: |

3~25 cans/minute |

|

Torque: |

10 N/M |

|

Rated speed: |

1500 rpm |

|

Torque / speed: |

no change |

|

Servo motor power: |

1.5kw |

|

Stirring motor power: |

0.4kw |

|

Outline length, width and height: |

3000*850*2100 (height customized with the height of the bottle and conveyor line) |

|

Main machine power: |

1.9kw |

Certificates and Factory

Partners