The aluminum-plastic blister packaging machine is a machine specially designed and produced for small pharmaceutical factories, health product factories, food factories, hospital preparation rooms, etc. Aluminum-plastic blister packaging machines are mainly used for packaging solid medicines and foods such as capsule, tablet, big honey pill, candy, liquid, paste and so on.

Product Name :

DPP-150 Plate Automatic Blister Package MachineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

145*110*35mm(customized)After-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

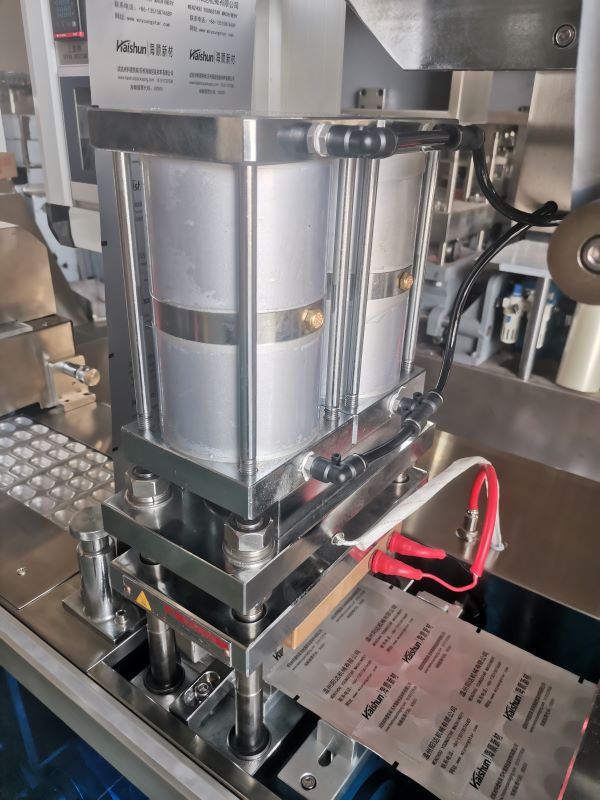

The product is specially designed for hospital dosage room, laboratory institute, health care product, middle-small pharmacy factory, and featured by compact machine body, easy operation, multi-function, stroke adjustable, long durability etc, it is suitable for the Alu-PVC package of medicine, food, electric parts etc. Aided forming Pre‐cutting Inspection and rejecting control systems.

Main Features

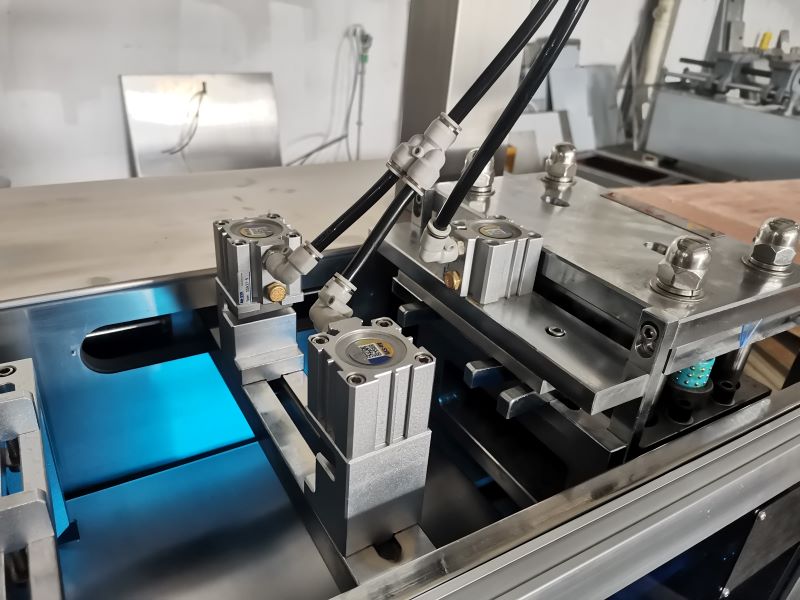

1. Traction drive by servo motor, with precise synchronization. The length of travel range can be set in man-machine interface. The traction stroke can be adjusted within the range of 10 to 500mm, which expands the application range of the machine.

2. Equipped with eye marking system, the background of printed pattern is uniform and looks pleasant.

3. Available for alu-plastic (hot forming) and alu-alu (cold forming), only change mould and feeder for alu-alu packing.

4. The electrical appliances adopt imported control system, and can be equipped with missing material mending device and missing grain detecting and rejecting device according to user's requirements.

5. The whole machine adopts segmented combination: PVC forming, filling and heat sealing as one section, tropical aluminum cold forming, heat sealing and punching as one section, so as to realize segmented packaging.

6. Adopting photoelectric control system, PVC, PTP, Duralumin packaging automatic feeding, waste edge automatic punching and cutting device, to ensure ultra-long distance multi-station synchronization and stability.

7. It utilizes frequency conversion stepless speed regulation, with blanking frequency 10~55 times/min.

8. Automation by PLC and operation through touch screen control panel.

Forming

Filling and feeding device, filling rate reaches 99.5%

PLC control system

Automatic punching

Adjustable size according to roll of material and record

Equipped with eye marking system

cutting device

Finished product outlet and the waste edge will be 1-2mm can be adjusted

Collect the waste edge

Main Technical Parameters

|

Machine model |

DPP-150 |

|

Maximum yield |

1200-42-- tablets / hour |

|

Blanking frequency |

10-35 times/minute |

|

Maximum molding area |

145*110*35 MM |

|

Standard travel range |

50-120 MM |

|

Mold Cooling |

Tap water or Circulating water |

|

Power of Main Motor |

1.5KW |

|

Total Power |

3.8KW |

|

Power |

380V/220V 50Hz |

|

Noise index |

<75dBa |

|

PVC hard sheet |

0.15-0.5*150 MM |

|

PTP aluminum foil |

0.02-0.035*150 MM |

|

dialysis paper |

50-100g*150 MM |

|

Vacuum |

0.4MPa-0.6MPa |

|

weight |

850 KG |

|

size |

2300*950*1500 MM |

Certificates and Factory:

Partners: