It can be used in paper-plastic composite, plastic composite, aluminum-plastic composite, PE re-feeding bag packing machine, etc. the packing bag pattern, the sealing quality is good, thus raised the product grade; Only according to different materials with different measuring devices can be used to achieve particles, powder, bulk, liquid, soft cans, toys, hardware and other products of automatic packaging.For large enterprises, small and medium-sized enterprises to achieve packaging automation, saving labor costs and management costs, significantly reduce costs.

Product Name :

Full automatic bag packing machineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

Packaging materials:PET/AL/CPP composite film bag;Packing size:Width of bag: 100mm~210mm, Bag length: ≤350mmAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

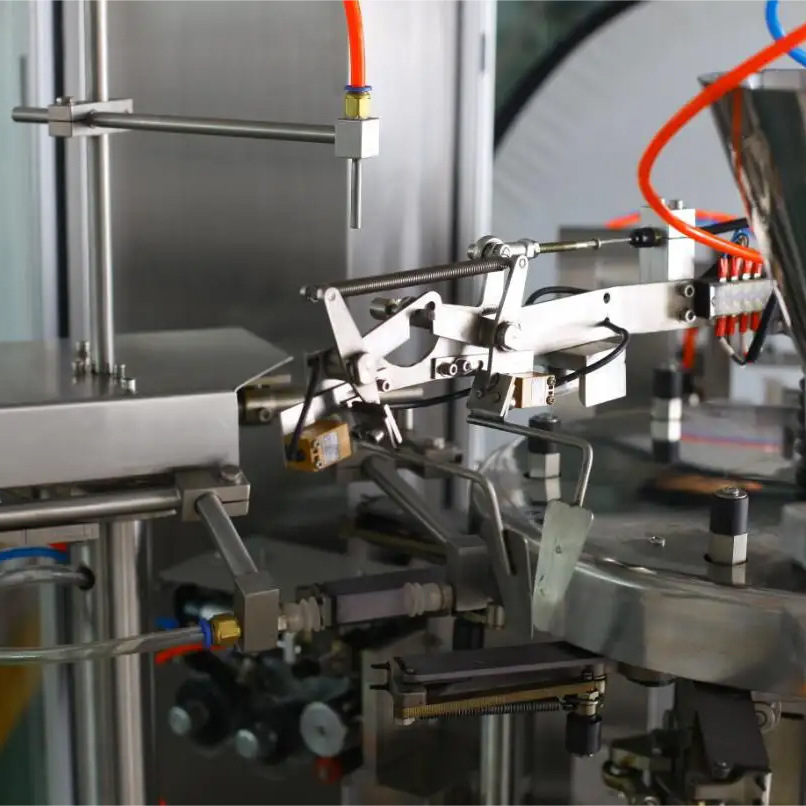

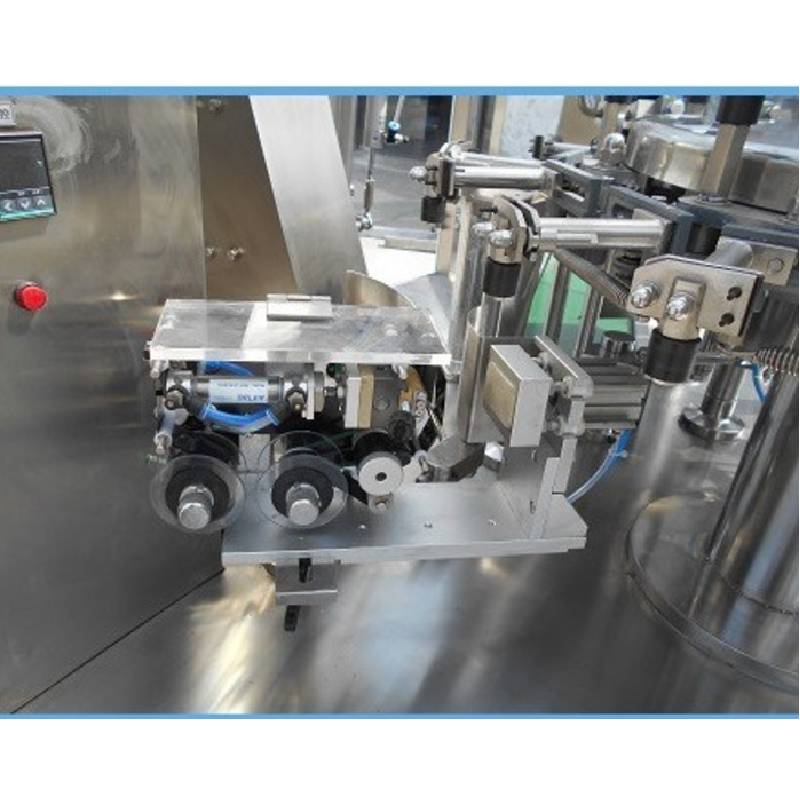

1Detailed display:

Product Features:

1. Intelligent detection of whether or not to open the bag and open the bag is complete, in the case of not suitable for filling not hot sealing, not waste bags, can save considerable cost for users.

2. The working speed of the machine can be adjusted by the frequency conversion speed regulating device at will within the specified range.

3. Equipped with advanced Siemens PLC control, touch screen man-machine interface operation more convenient.

4. Overload protection, safety device. The machine in the work of abnormal air pressure or heating tube failure automatically alarm tips.

5. It can realize double feeding, solid and liquid adding, different liquid adding and so on.

6. The clamp width of each group can be controlled and adjusted by motor, which is suitable for bags with different widths.

7.In some components with imported tolerance plastic bearings, no need to oil, reduce the contamination of food.

8. All the parts in contact with the packaging bags or materials are made of stainless steel and other materials which meet the requirements of food processing.

9. It can be used for weighing materials with different metering devices. It can be used for packaging of liquid, paste, granule, powder, irregular block and other materials.

10.The use of prefabricated product packaging bags, patterns, sealing effect is good, high-grade finished products.

11. It can pack prefabricated bags and paper bags made of multi-layer composite film, single-layer PE, PP, etc.

Main feature:

1.LCD touch screen. Smart touch screen, support more than language,can store multiple parameters.Pneumatic pump metering device, high-precision pneumatic pump, adjustable capacity, according to the packaging capacity adjustment parameters, easy to understand the operation.Heat seal device, constant temperature heat seal, ensure the precision of sealing, no air leakage, no material leakage.

2.Automatic bag pick-up,Automatic color bar coding,

Finished bag device, can place 600 bags, mechanical automatic bag opening.

3.Automatic operation, automatic detection function, no bag not filling, no bag not sealing.

Main Technical Parameters :

|

Machine model |

Full automatic bag packing machine |

|

Packaging materials |

PET/AL/CPP composite film bag |

|

Packing size |

Width of bag: 100mm~210mm, Bag length: ≤350mm |

|

Form of packing bag |

Flat Bag, self-standing bag |

|

Packing speed |

≤50 bags/min |

|

Host power |

0.75KW/4P /AC380V |

|

Output motor power |

0.1KW/4P /AC380V |

|

Vacuum pump power |

0.5KW/4P /AC380V

|

|

Exhaust pressure |

0.8 Mpa/exhaust volume ≥0.4/min |

|

Total power of power supply |

380V |

|

weight |

1200KG |

|

size |

2100×1700×1750mm |