Fully automatic capsule filling machine is suitable for filling powder, granules, oil or liquid to empty capsules

A Capsule Machine, Capsule filler, capsule filling machines, also called Encapsulators or encapsulation machines are machines commonly used in the pharmaceutical, nutraceutical industries to fill empty soft or hard gelatin capsules of various sizes with powders, granules, semi-solids or liquid substances containing active pharmaceutical ingredients or a mixture of active drug substances and excipients. This process of filling empty capsules with substances is termed encapsulation.

Product Name :

Fully automatic capsule filling machineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

Capsule size 00#-5# and safety capsule A-EAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

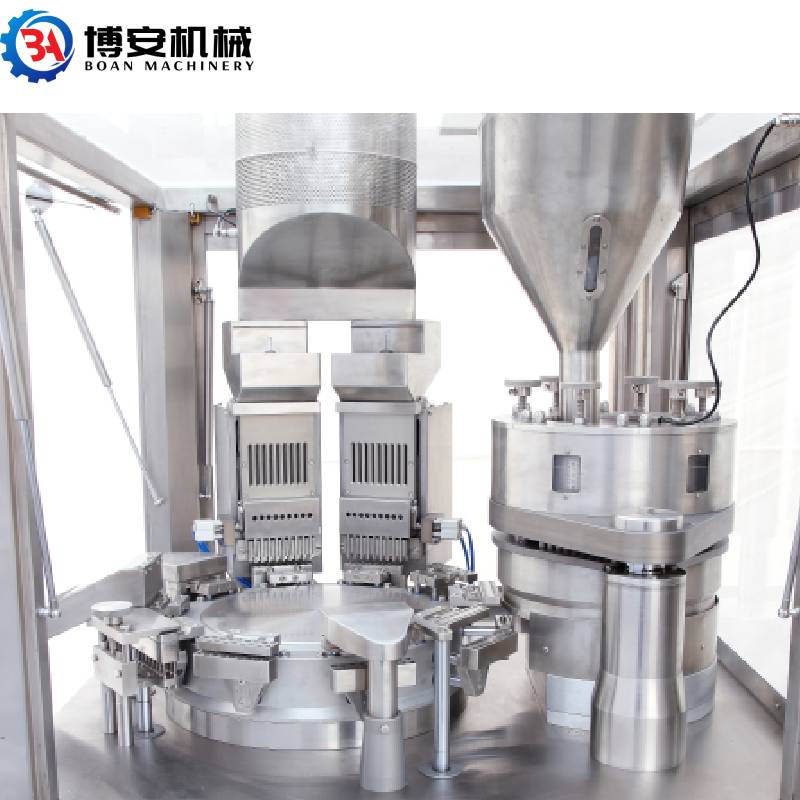

Our machines are specially designed to meet your unique production requirements from a Semi automatic capsule machine to fully automatic high speed production. United Pharmatek's capsule fillers incorporate the best technology to help you successfully and easily dispense accurate dosages for every capsule produced.

United Pharmatek's Fully Automatic Capsule Filling Machine finished product output can range from 900 gelatin capsules per minute up to 2,500 per minute. Each capsule filler automatically orientates, opens the empty hard gelatin capsule, properly fills the capsule with powder, and automatically closes the capsules. Our capsule filling machines are suitable for filling capsule sizes ranging from 00 to 4.

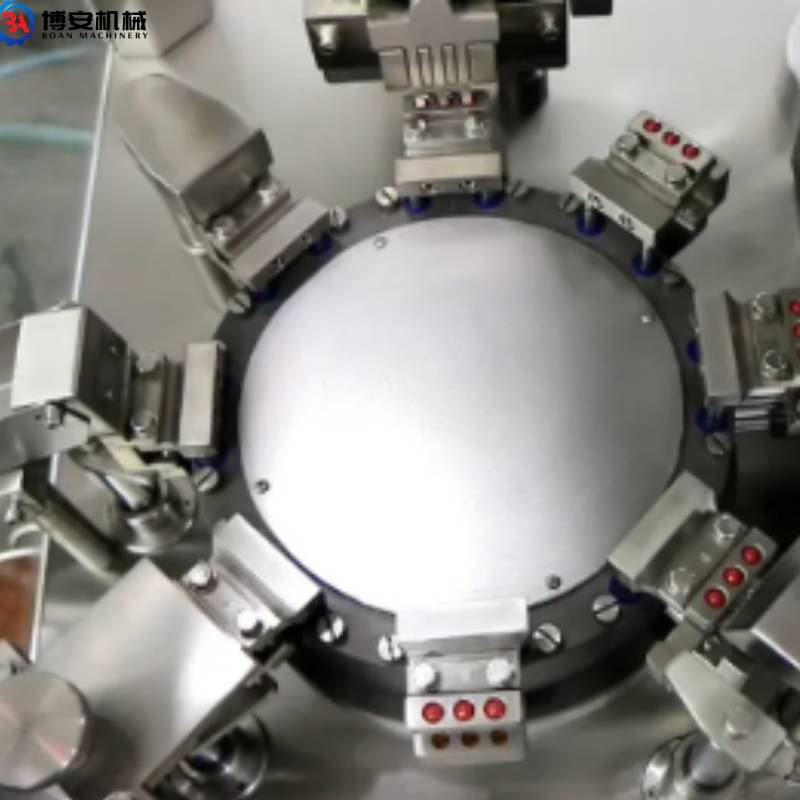

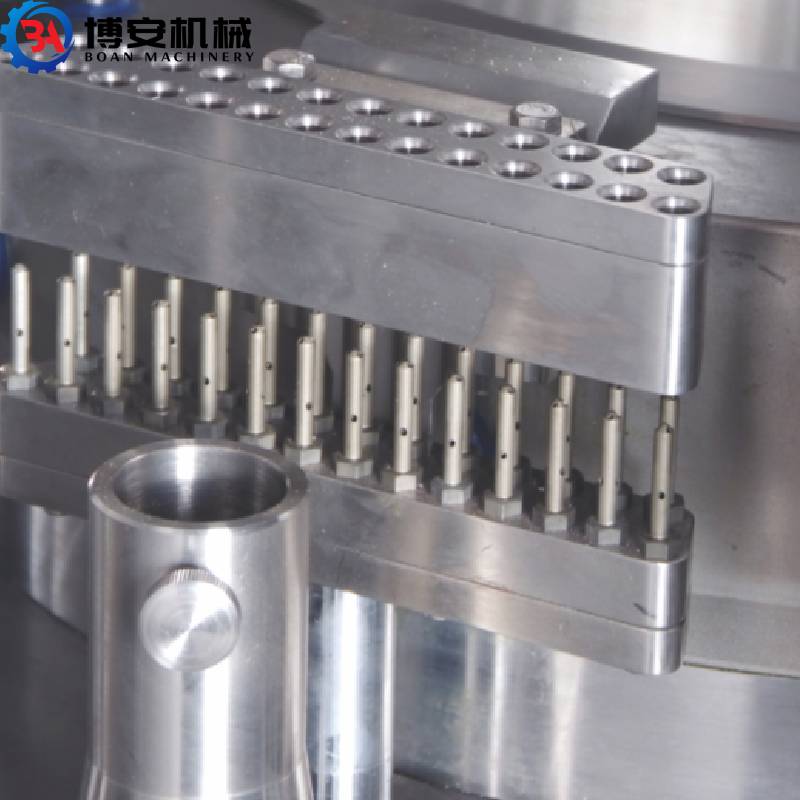

Method of capsule fillingis by utilizing the tamping style system, each tamping station can be adjusted individually for precision capsule fill weight control. An adjustable gap between the Dosing Disk and the Tamping Plate ensures minimum spillage of powder. The Automatic Capsule Filling Machine includes sensors for both product hopper and empty capsule hopper to ensure continuous uninterrupted operation providing the best method on how to fill empty capsules.

Main Features:

Exclusive Features of Automatic Capsule Filling Machine

Compact cGMP model.

Programmable Logic Control (PLC) & display of all operations

All the drive elements and the cabling at the bottom side separate panel

Crevice free smooth stainless steel pharmaceutical grades

Automatic intermittent motion Driving Zone completely separate at bottom and production zone at upper side.

Fill weight can be easily achieved by dosing disk thickness; the weight variation can be maintained ± 3% by accurate dosing disc.

Powder sensor maintains constant level of powder in the dosing chamber and there will alarm in case of low level of powder in dosing chamber.

Easy to operation by central control touch screen and easy to change dosing disc, tamping pins, capsule feeding & orientation parts, capsule segments.

Product contact parts are 316L SS and the other parts non-corrosive material.

Capsule can fill powder or pellets.

Non-separated capsule will be ejected automatically.

Option of attaching Capsule Polisher Line which includes capsule polishing, sorting, metal detection machines.

IQ/OQ documentation can be provided.

Sampling system can be provided on demand.

Main Technical Parameters

Delivered with 3 working days

Maximum Output of 48,000 Per Hour

Overall Size 920x785x1990mm

Weight 800kg

UK 380V Three Phase / USA 220V

Free Life Time Support & Training

German Touch Screen, PLC System and Frequency Conductor (Siemens Brand)

German 1.6KW Main Motor and 1.5KW Dry Vacuum Pump (Becker Brand).

Precision Engineered Japanese Bearings.

French Electrical Parts.

Taiwan High Precision Cam Index Unit.

Over 99.5% Full Capsule Accuracy Rate

Pre Set Ready to Use

Save 5-10% on are basic model

About us :

Partners :