Pharmaceutical, medicine, and chemicals (powder, Pellet, granule, pill), also can be used to fill vitamin, foodstuff and animal drug, etc.

Product Name :

NJP-260 Automatic capsule filling machine Liquid/Oil capsule fillerCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

Capsule size 00#-5# and safety capsule A-EAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

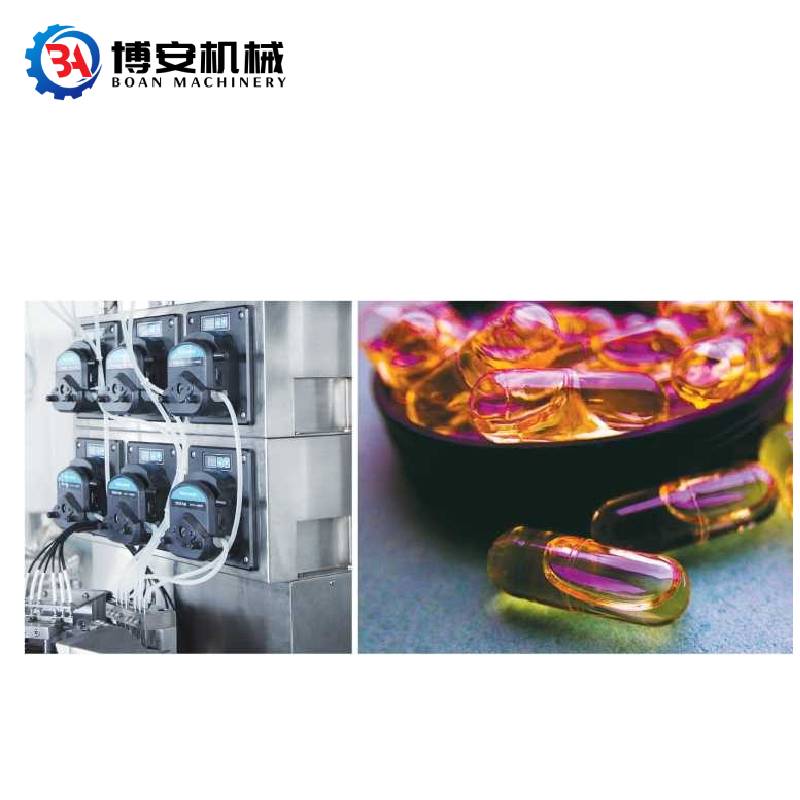

The NJP-260 Automatic capsule filling machine is a high-speed machine designed for filling capsules with liquid or oil substances. It is commonly used in pharmaceutical and nutraceutical industries for producing capsules with precise dosages.

Key features of the NJP-260 Automatic capsule filling machine include:

High-speed filling: This machine can fill up to 260 capsules per minute, ensuring high production efficiency.

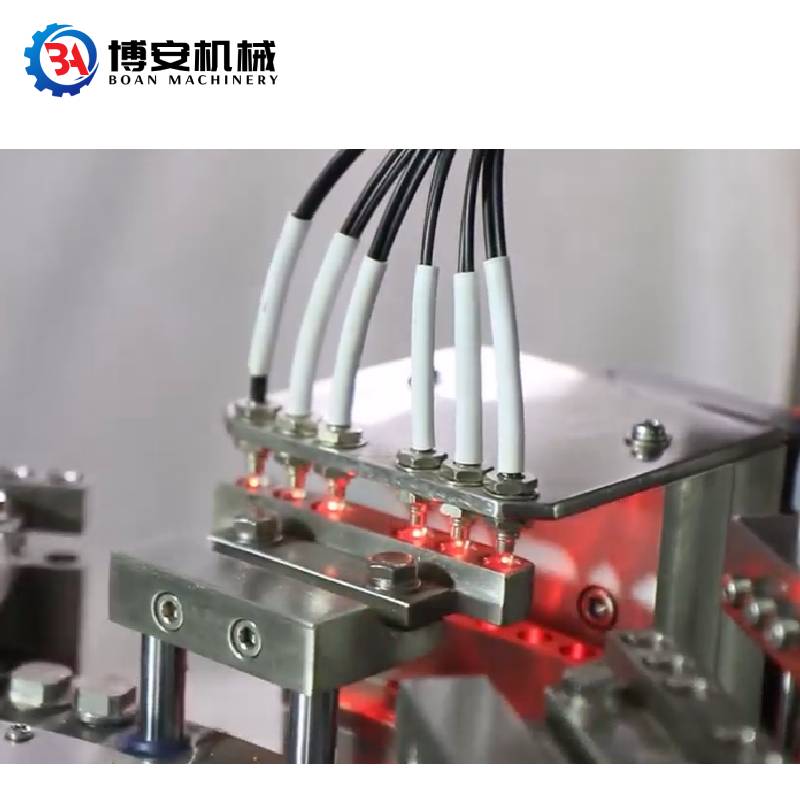

Accurate dosing: The machine is equipped with a precision dosing system that ensures accurate filling of liquid or oil substances into each capsule.

Easy operation: The machine is user-friendly and easy to operate, with a touch screen control panel that allows for easy adjustment of parameters and monitoring of the production process.

Versatile capsule sizes: The NJP-260 can handle a wide range of capsule sizes, including 00, 0, 1, 2, 3, 4, and 5, providing flexibility in production.

Quality assurance: The machine is designed to meet GMP standards, ensuring the highest level of quality and hygiene in capsule production.

Automatic capsule sorting: The machine is equipped with an automatic capsule sorting function, which removes any defective capsules, ensuring only high-quality capsules are produced.

Easy maintenance: The NJP-260 is designed for easy maintenance and cleaning, with easy access to all components for routine maintenance and troubleshooting.

Overall, the NJP-260 Automatic capsule filling machine is a reliable and efficient solution for filling capsules with liquid or oil substances, offering high-speed production, accurate dosing, and easy operation.

Main Features:

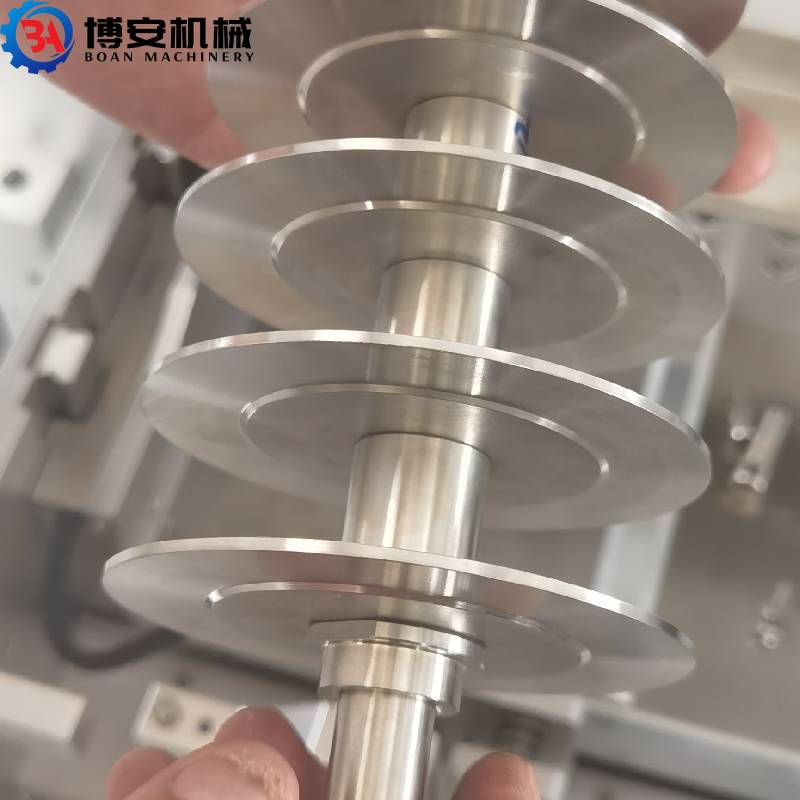

1.Improve the driving cams of all stations, from original outer cam pulled by spring to inner groove cam made of high-quality special material. This change, eliminating the disadvantages of easy fatigue and short service life for spring pulling method, makes the machine more wearable and stable.

2.In consideration of the medicine dust easy to enter the machine mould after long-time running, causing the mould rotary plate to be disassembled for cleaning, the innovation design of seal ring preventing dust from outside is developed and applied to this machine, which completely ensures the sealing in running process and eliminates the shortcoming of tedious maintenance.

3.This machine adds the inching control system, convenient for the human-oriented operation in manufacturing and cleaning process.If lack of capsule, the liquid feeding will stop automatically.

4.The maximum production capacity of this machine can reach 260 capsules per minute. Standard and serial production: the interchangeability of manufacturing parts can reach above 99%; each spare part has its own regular code; while changing the mould, all the parts are fixed by the location hole with high precise; it’s very efficient to change the moulds, easy to operate and clean the machine.

Main Technical Parameters

|

Model |

NJP-260 |

|

Machine Weight |

900KG |

|

Overall Dimension |

1020*860*1970mm |

|

Motor Power |

5.75KW |

|

Power Supply |

3 phase, four-wire AC 380V 50Hz |

|

Max. Capacity |

260pcs/min |

|

Capsule Size |

00#-5#, secure capsule A-E |

|

Good Filling Rate |

≥99.5% |

|

Noise Index |

≤75dBA |

|

Precision |

Liquid more than 300mg≤±3% |

|

Compressed Air |

0.06m3/min 0.3MPa |

|

Source of Water |

Water-ring vacuum pump matching with water tank to recycle the water, or using external water source. |

|

Vacuum Degree |

-0.02 ~ -0.06 MPa |

|

Water Flowing Rate |

250L/h |

|

Inner Diameter of Inlet Tube |

20mm |

|

Inner Diameter of Outlet Tube |

27mm |

|

Working Temperature |

21℃±3℃ |

|

Plant Height |

Human feeding ≥2.6m, Vacuum feeding ≥2.8m |

|

Relative Humidity |

40-55% |

|

Air Displacement |

300m3/h |

|

Control System |

Stepless frequency converter, PLC control |

|

Material |

All the parts directly contacting with capsule and liquid adopt high quality of 304 and 316L stainless steel. |

About us :

Partners :