liquid capsule filling machines are highly automated and precisely controlled specialized equipment capable of efficiently producing various types of liquid-filled capsule products. They offer versatile performance and broad application scope.

Widely used in the production of liquid capsule products for the pharmaceutical, nutraceutical, and cosmetic industries.

Product Name :

BA-NSF 600 hard capsule liquid filling machineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

Capsule size 00#-5# and safety capsule A-EAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

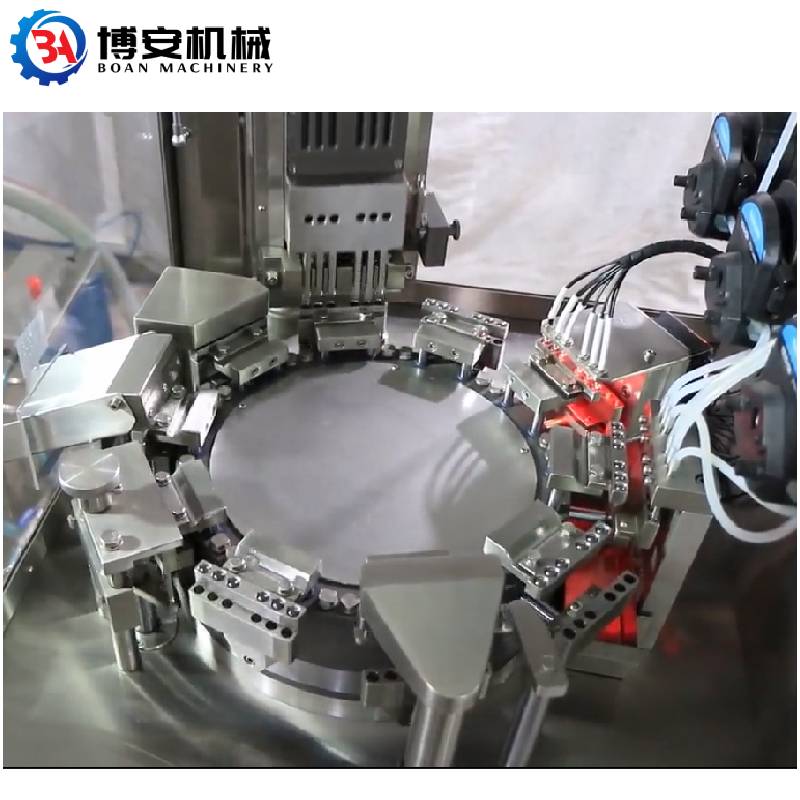

Working Principle:

Liquid capsule filling machines are primarily used to automatically fill liquid formulations into empty soft gelatin capsules.

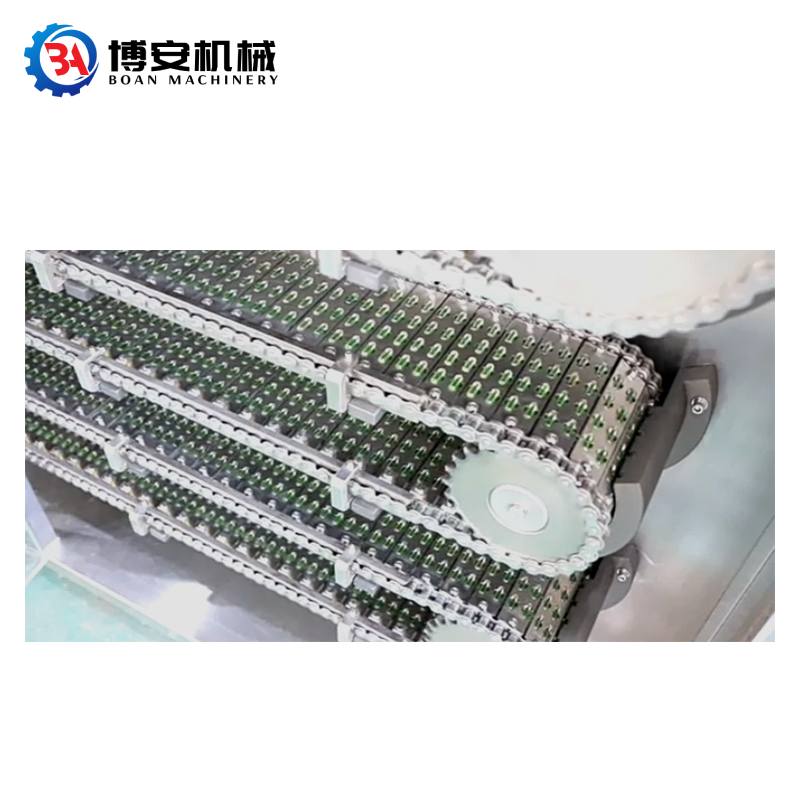

Capsule loading-sowing-splitting-inspection-filling-locking-discharging-sealing-drying

Main Components:

Hopper: Stores and supplies the liquid material.

Metering System: Precisely controls the volume of liquid filled into each capsule.

Capsule Supply System: Automatically feeds and positions the empty soft gelatin capsules.

Filling System: Dispenses the liquid material into the capsules.

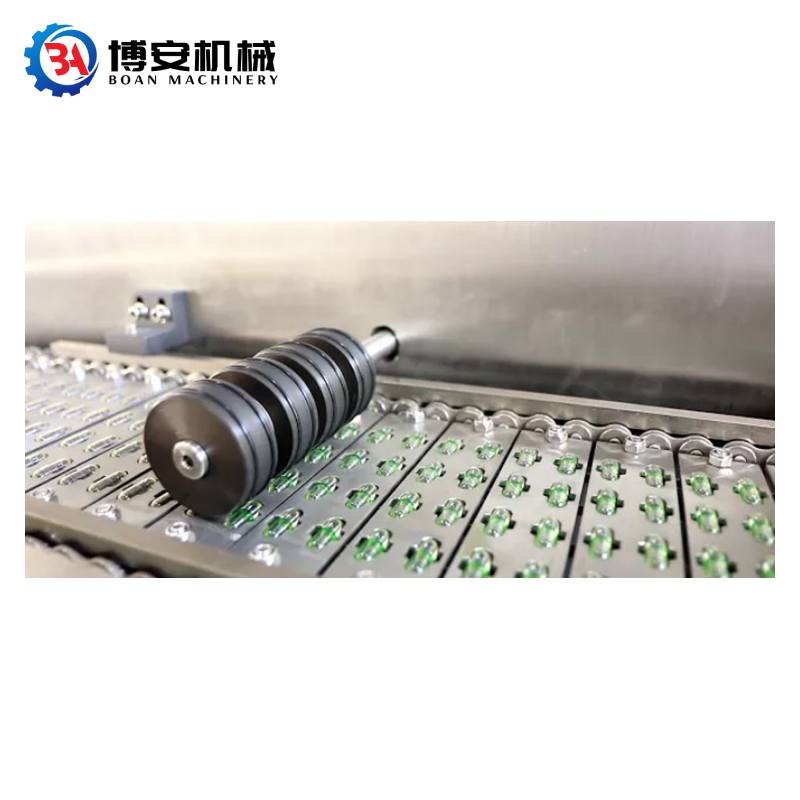

Sealing System: Seals the filled capsules.

Main Features:

Capsule sowing and splitting

Capsule inspection

Capsule filling

Capsule sealing

Capsule drying

Main Technical Parameters

|

Model |

BA-NSF 600 hard capsule liquid filling machine |

|

Machine weight: |

2000 KGS |

|

Dimension: |

3565*1100*2100 mm |

|

Motor power: |

7.75KW |

|

Power supply: |

Three-phase four-wire AC 380V, 50HZ |

|

Maximum production capacity: |

600 capsules/ minute |

|

Capsule model: |

00 # ~ 2 # and safety capsule A ~ E |

|

Capsule loading rate: |

≥99.5% |

|

Noise: |

≤75dBA |

|

Difference in loading liquid more than 300mg |

≤±3% |

|

Compressed air: |

0.06m3/min 0.3Mpa |

|

Water source requirements |

Water ring vacuum pump with water tank for recycling, or connected to the water source |

|

Vacuum degree: |

-0.02~-0.06 MPa |

|

Water flow rate: |

250L/h |

|

Inlet pipe inner diameter: |

20mm |

|

Inner diameter of drain pipe: |

27mm |

|

Working environment temperature: |

21℃±3℃ |

|

Height requirements of the working plant: |

manual feeding ≥ 2.6m, vacuum feeding ≥ 2.8m |

|

Relative humidity of working environment: |

40~55% |

|

Exhaust volume: |

300m3/h |

|

Control system: |

Frequency conversion stepless speed regulation, PLC control |

|

Material: |

304 high-quality stainless steel is used for the parts which are in direct contact with the capsule and liquid |

|

Special features Possibility: |

Adding the micro-pills or small size capsule filling can device |

Certificates and Factory:

Partners :