Pharmaceutical powder granule pellet fully automatic hard capsule filling machine 000#-5# capsule filling machine filling machine

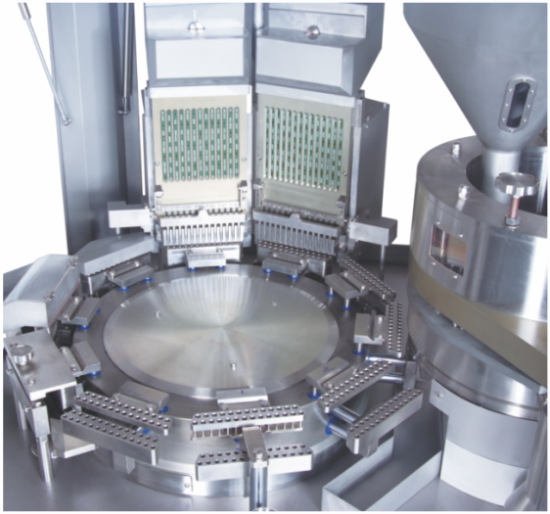

NJP-3800 series automatic hard capsule filling machine is suitable for batch production. This product is a practical new product, filling hole type automatic hard capsule automatic filling device is completely closed, easy to fill and rotate parts, up and down modules move in one direction, imported double lip polyurethane sealing ring, sealing performance is good, the module cleaning station adopts the way of combining blowing and blast to ensure high-speed operation and no dust. The locking station is provided with a powder suction device. The finished product comes out of the pocket with a balloon ring, no dust.

Product Name :

Pharmaceutical powder granule pellet fully automatic hard capsule filling machine 000#-5# capsule filling machine filling machineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

Capsule size 00#-5# and safety capsule A-EAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Product Features:

1.Total Enclosure Turning Table: Easy cleaning is facilitated by the adoption of a total enclosure turning table, ensuring a clean production environment and easy maintenance.

2.Single Movement with Two-Lip Seal: The upper and lower segments move together with a two-lip seal, offering enhanced sealing performance, preventing leakage, and maintaining product integrity.

3.Combined Air Blowing & Suction Function: The segment cleaning station employs a combined air blowing and suction function, ensuring efficient cleaning even at high speeds, effectively removing debris and residue.

4.Dust-Preventing Rubber Block: Equipped with a dust-preventing rubber block at the capsule discharge station, minimizing contamination and ensuring the cleanliness of the final product.

5.Efficient Automation: NJP-3800C boasts highly automated features, facilitating fast and accurate capsule filling, thereby improving overall production efficiency.

6.Versatility: Capable of handling various types and sizes of capsules, ranging from size 00 to size 5, making it adaptable to different production needs.

7.Precise Filling Amount Control: Utilizing a precise control system, the NJP-3800C ensures consistent and accurate filling amounts for each capsule, maintaining product quality standards.

8.Ease of Operation and Adjustment: Designed for simplicity, the equipment is easy to operate and adjust, enabling operators to quickly adapt to changing production requirements.

9.High-Quality Construction: Constructed with premium materials and advanced manufacturing techniques, the NJP-3800C offers stability, durability, and longevity, suitable for long-term production use.

10.Safety and Reliability: Equipped with multiple safety functions and protection devices, such as fault detection systems and emergency stop buttons, ensuring operator safety and minimizing risks during operation.

11.Cost Saving: By reducing labor costs and production time while improving efficiency, the NJP-3800C contributes to cost savings for businesses, enhancing competitiveness in the market.

Main feature

POINT01:No need for air source

POINT02: The scrap removal mechanism adopts a modular design,which is easy to disassemble and has good visibility.

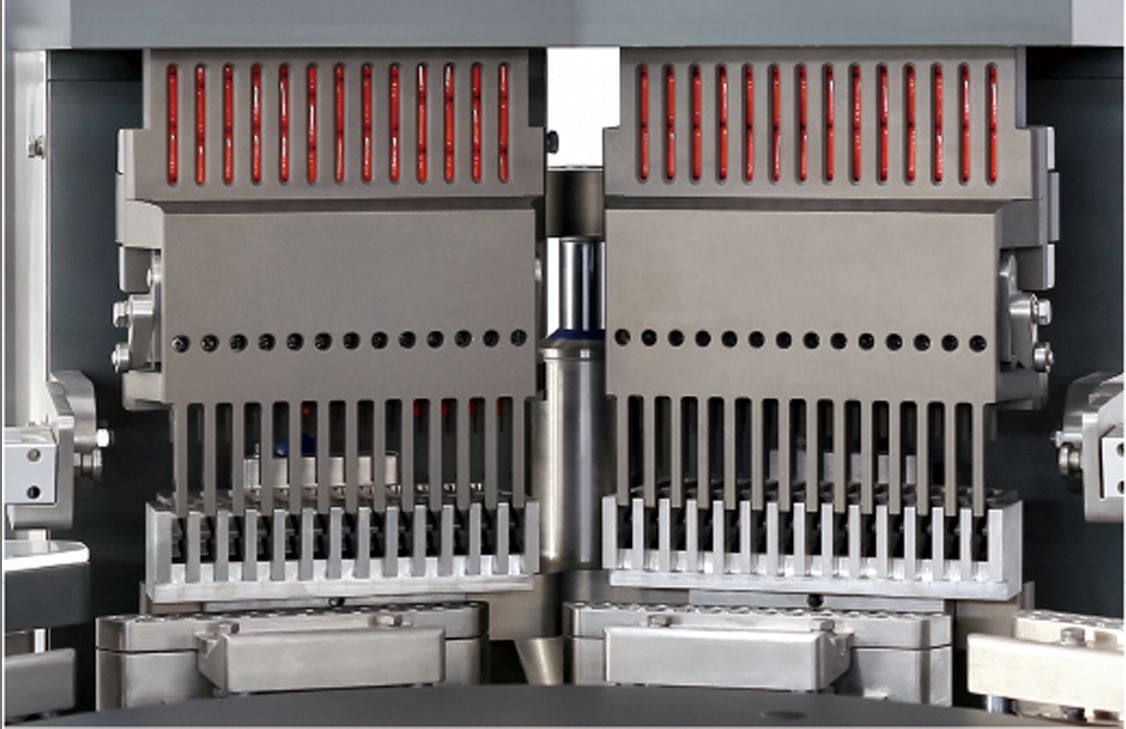

POINT03: The main board, guide groove, and shift fork adopt modular design, which is easy to disassemble and quick to replace.

POINT04:Siemens brand controller ensures the stability of the electrical control system.

POINT05:Purify the compressed air and thoroughly remove the dust in the mold hole

POINT06:One click and one twist, easy to fix,

The filling rod holder has a modular pull-out design, making it easy to replace the mold in 15 minutes.

POINT07:Oil-free bearings, hassle-free,PTFE oil-free bearings, say goodbye to greasiness and no need to refuel

Main Technical Parameters:

|

Machine model |

NJP-3200B/C/E |

NJP-3800B/C/E |

|

Filling form |

Powder, granule, tablet |

|

|

Suitable capsule model |

(00#-5# capsule / safety capsule A-E) |

|

|

Maximum yield |

1920,000 tablets / hour |

228,000 tablets / hour |

|

Power requirements |

380V 50Hz 4.77kw |

380V 50Hz 6.37kw |

|

Noise index |

≤78dBA |

|

|

Outer size |

1440×1300×2080mm |

1440×1300×2080mm |

About us :

Partners :