Pouch filling machines are specialized equipment used in the flexible packaging industry to fill and seal pre-made pouches or bags with various products such as liquids, powders, or granules. These machines play a crucial role in automating the packaging process, improving efficiency, and ensuring consistent product quality.

Product Name :

Pouch filling machines for flexible packaging 200/250/300Certification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

Packaging materials:PET/AL/CPP composite film bag;Packing size:Width of bag: 70mm~200mm, Bag length: 150-25-/200-300mmAfter-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1

Pouch filling machines are widely used in industries such as food and beverage, personal care, pharmaceuticals, and chemicals, where flexible packaging is preferred. They can handle a variety of products, including liquids, pastes, powders, and granules, ensuring efficient and consistent packaging.

Main features:

Key Components of a Pouch Filling Machine

1, Pouch Feeding System: Responsible for automatically feeding the pre-made pouches into the machine.

2, Filling System: Includes the filling nozzle, volumetric or gravimetric filling mechanism, and product hopper or tank to accurately dispense the desired amount of product into the pouches.

3, Sealing System: Utilizes heat, impulse, or ultrasonic sealing technology to securely close the filled pouches.

4, Pouch Handling Mechanisms: Includes conveyors, guides, and other mechanisms to transport the pouches through the different stages of the filling and sealing process.

5, Control System: Provides automated control and monitoring of the machine's operations, including fill volumes, sealing parameters, and production speed.

6, Frame and Structure: The sturdy frame and housing that supports and encloses the various components of the machine.

Additional Components

7, Pouch Printer or Labeler (optional): For printing or applying labels to the filled pouches.

8, Checkweigher (optional): Ensures the filled pouches meet the desired weight specifications.

9, Rejection System (optional): Automatically identifies and removes any defective or non-compliant pouches.

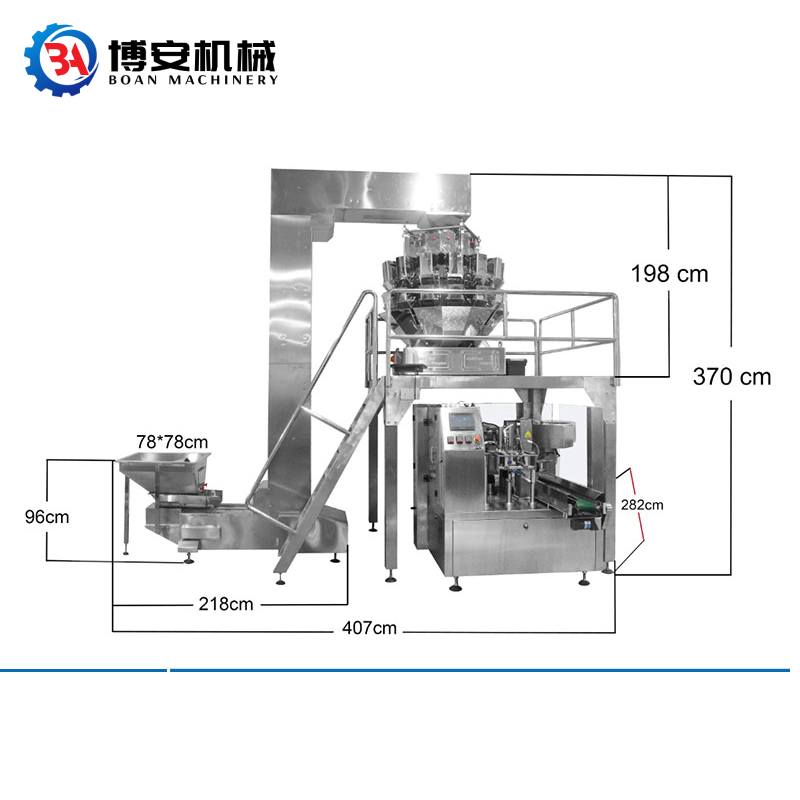

Main Unit

Z type lifting

PLC Control System

Touch screen. Smart touch screen, support more languages

Pouch Feeding System

Pouch Printer or Labeler

Main Technical Parameters :

|

Machine Model |

Pouch filling machine 200/250/300 |

|

Packaging materials |

PET/AL/CPP pre-made bag |

|

Packing size |

W: 70—200mm(L: 150-250/200-300mm) |

|

Packing speed |

10-65 bags/min |

|

Filling range |

10g-2500g |

|

Total power |

380V, 50/60Hz 2.5KW |

|

Applicable range Various types |

sauce, granule, powder, irregular materials |

|

Bag opening method |

Vacuum bag opening |

|

Compressed air consumption |

0.6 cubic meters / min |

|

Weight: |

1350kgs |

Certificates and Factory:

Parnters: