This machine is widely used for mixing dry powder in pharmacy, chemical industry, food industry, etc., as well as for the quickly and evenly mixing several kinds of materials that with different proportion and different size.

Product Name :

SBH-10/20 /50 Model 3D Motion Mixer /Blender /Mixing MachineCertification :

cGMP CE ISO SGS and etc.Lead Time :

15 Days Fast Delivery.Loading Port :

Guangzhou/Shenzhen / ShanghaiProduct Function :

10/20 /50After-Sales Provided :

Engineers available to service machinery overseas.Warranty :

1 YearsMOQ :

1Overview

SBH-10 Three dimension Mixer are widely used in different industries to mix various fluid powders and granules. Driven by a driving shaft, our mixer repeatedly performs a combination of translational movements, rotational rotations, and tumbles to promote good compound three-dimensional movement of the material along the cylinder.Under our unique mixing motion, the flow and diffusion of various materials can be accelerated during the mixing process. At the same time, our 3D mixer avoids the separation and accumulation of tray specific gravity caused by centrifugal force. The three-dimensional mixers serve the pharmaceutical industry, chemistry, food, and metallurgical research.

During running, as the mixing vat is able to make multi-directional actions of motion, which speeds up the flowing and diffusing effect of material in mixing process, meanwhile it also avoid phenomenon of segregation and accumulation caused by centrifugal effect in ordinary mixer, and it has no dead corner, therefore, it can guarantee the best quality of mixed raw materials.

Main Features

1.Due to the mixing barrel has a multi-directional movement, so that the barrel of the material mixing points, mixing effect is remarkable, its mixing uniformity is higher than the general mixer, the drug content of the uniformity of the error is lower than the general mixer. At the same time SBH series of three-dimensional movement mixer maximum loading volume than the general mixer to be more than double (general mixer maximum loading volume for the barrel volume of 40%).

2.SBH series of three-dimensional movement mixer mixing barrel design is unique, the barrel body wall after fine polishing, no dead ends, no contaminated material, the material discharged under its own weight smoothly discharged, leaving no residual material, with no pollution, easy to discharged, no accumulation of material, easy to clean and other advantages.

3.Materials are mixed under closed condition, which will not pollute the working environment.

Front side+CE certificate+Three-dimensional mixer with emergency stop switch+ Main power switch+Tap switch+ Frequency conversion speed control

Front side+CE certificate+Three-dimensional mixer with emergency stop switch+ Main power switch+Tap switch+ Frequency conversion speed control

Three-dimensional mixer hopper

Three-dimensional mixer material outlet

Three-dimensional mixer material inlet connection

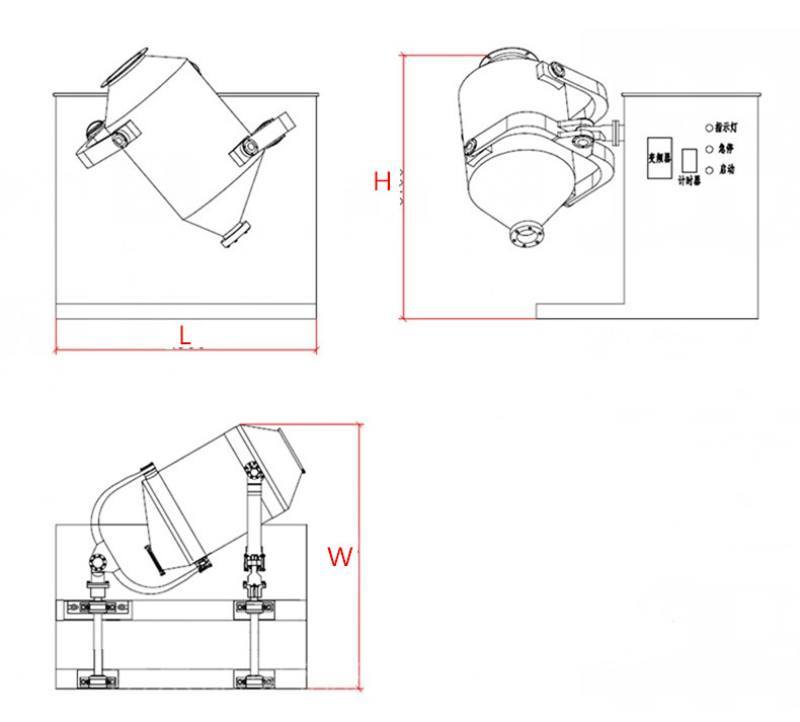

Product Structure:

Main Technical Parameters

|

Model |

10 |

20 |

50 |

|

Volume of barrel (L) |

10 |

20 |

50 |

|

Max. Loading volume(L) |

5 |

18 |

40 |

|

Max. loading(kg) |

3 |

15 |

20 |

|

Rotary speed of main shaft(r/min) |

0~30r/min |

0~12 |

0~12 |

|

Power(kw) |

0.55kW |

0.55kW |

1.5Kw |

|

Weight(kg) |

100 |

150 |

300kg |

|

OutSize dim (mm) |

880*720*800mm |

920*800*900mm |

1200*900*1150mm |

Certificates and Factory:

Partners: